Material flow simulation

Reliable planning for an optimized material flow

Customer-specific material flow simulations for your project

Investigations of production lines during operation are cost-intensive, time-consuming and cannot be repeated. In the event of planning a new production line, they are not feasible. In contrast to this, material flow simulations are inexpensive, offer innumerable possibilities for variation and are therefore an important step on the way to digital production planning. Due to many years of simulation experience with more than 75 successfully completed projects in combination with the high-performance software "Plant Simulation" from Siemens, we are able to generate high-quality models. These form the basis for a high level of planning security and, using the appropriate know-how, lead to optimized proposed solutions for your project.

Your benefits at a glance

Security

Concept validation and comparison in the planning of production lines

Optimization

Simulations to optimize the performance of existing stations or lines

Time saving

Significant reduction in development and planning times for new systems

Cost saving

Inexpensive simulations without affecting ongoing operations

Individuality

Simulation adapted to individual needs

Complexity reduction

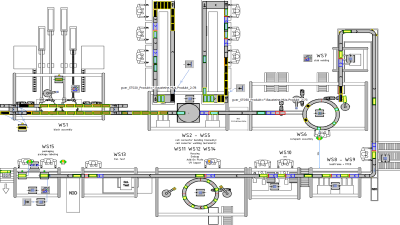

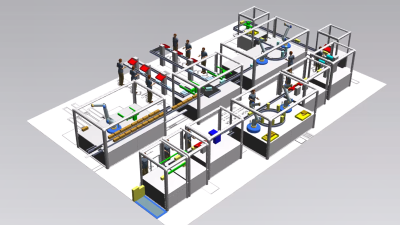

Simple and understandable representation of complex processes and procedures in 2D and 3D

Managing complexity, identifying vulnerabilities

You can use material flow simulations in different phases of the product life cycle of individual stations or even entire systems. Material flow simulations can significantly shorten the development and planning time of new lines but also of ramp-up phases and optimize processes even before the line has been completely set up or even designed. Would you like to improve the performance of existing stations or lines or do line extensions? We can investigate the additional effort or benefit within a very short time. Whether it is the optimal coordination of integrated robots and handling units or extensive line concepts, the use of several processing loops or the optimization of the supply: As experts for a large number of production processes such as dispensing, screwing or a wide variety of joining and pressing processes, we will find a solution.

Your way to efficient material flow

Are you planning a new factory or plant and the associated processes such as logistics processes? Do you need support in planning the material flow and possible transfer technology? We enable the simple and understandable presentation of your complex processes and procedures and lay the foundation for important investment decisions.

Planned or existing project? What information is expected from the simulation? Should different concepts be compared and recommendations for action derived? An early definition of relevant result key figures enables the determination of key figures and ensures optimal results for the areas of cycle time, throughput time, workpiece carrier or AGV number, buffer, warehouse and supermarket dimensions, set-up loss, station, equipment and worker utilization, and much more.

The key to a successful simulation is the input data. Layout information is just as relevant as station-related data. This includes, for example, process times, availabilities or dimensions. Transfer-related information such as buffer capacities, lengths and speeds are essential for the most accurate and meaningful representation of the material flow. In order to compile the necessary data quickly and efficiently, we are happy to assist you in personal discussions, with a guide and our many years of knowledge.

As soon as all the necessary information is available, the model is created. After the model has been completed, an extensive model validation takes place. Then the actual implementation of the experiment begins. After completion of the experiments, the collected raw data is evaluated and evaluated and the results are processed. Depending on your wishes, we will create meaningful reports or concise management reports with targeted solutions. For a better understanding of you or your management, we also create meaningful visualizations in the form of videos, picture sequences or result graphs.

After reviewing the results, further questions typically arise. We will be happy to support you in answering them. Should further knowledge be obtained in the course of commissioning or operation of a system, we are available at any time for further investigations or model extensions. Thanks to extensive documentation on our part, this can be carried out quickly and easily.